The benefits of laser cutting in industrial production

Laser cutting is an indispensable method in the industrial manufacture of metal parts, thanks to its unique combination of precision, speed and efficiency. It can cut metal materials up to 1.5 inches thick, minimizing the imperfections often observed with other cutting methods. This precision is essential in sectors where part quality and conformity are essential.

In addition to its precision, the speed of the process is a major advantage. This speed increases productivity while maintaining high quality results. By reducing material waste and optimizing resources, laser cutting also helps keep production costs down.

This process is also highly versatile. It can be adapted to a wide variety of metals, from steel to aluminum, while offering great freedom in the realization of complex shapes. As a result, manufacturers benefit from a flexible method, capable of handling limited series or large-scale production runs without significant process changes.

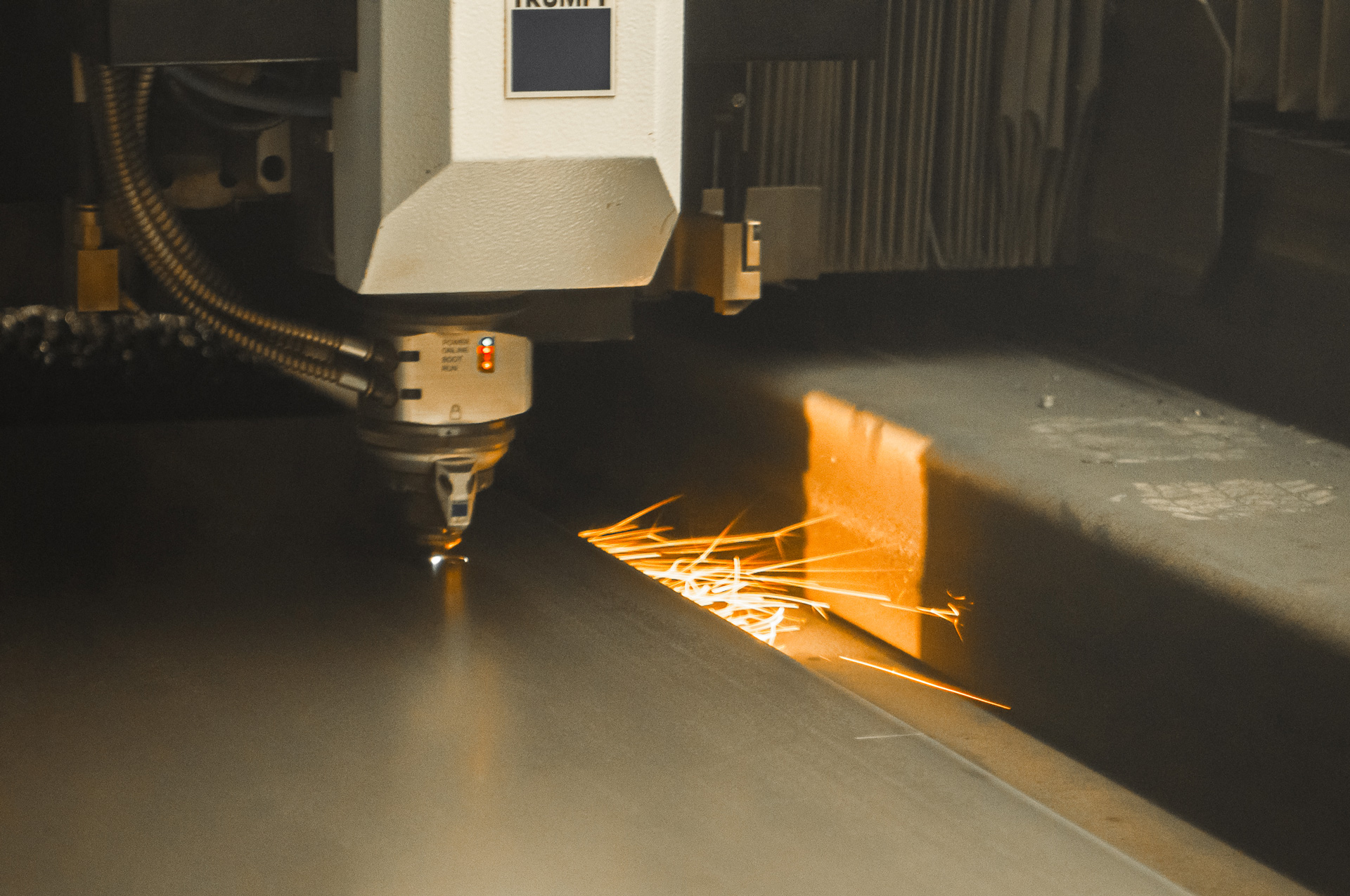

What sets laser cutting services apart is their ability to combine precision, speed and cost reduction. These characteristics make it a valuable asset for any company seeking to produce metal parts to exacting specifications, while optimizing resources and productivity. That’s why we offer this service with our Trumpf 10,000-watt fiber laser cutting equipment with automation and our Finn-Power 6,000-watt laser cutting system.